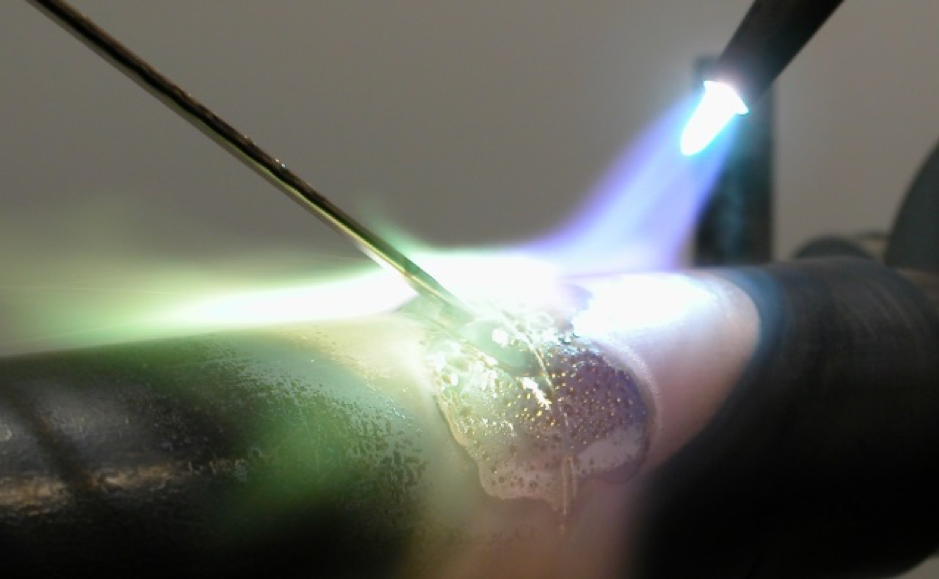

What Is Dip Brazing Process . dip brazing is an economical method of brazing multiple joint brazed parts, and large size dip brazing salt baths can help to dip braze a batch of. brazing is a fascinating process that connects metals using a filler material heated to a specific temperature range. In this article, we’ll dive. what is dip brazing? The assembly can be removed once the molten brazing filler metal has solidified. dip brazing is a widely used method in manufacturing and engineering industries for joining metal components. Brazing flux is applied to the parts to prevent oxidation. To braze is to join two or more pieces of metal by means of flowing a filler metal between the joint interfaces.

from exovxubli.blob.core.windows.net

In this article, we’ll dive. what is dip brazing? Brazing flux is applied to the parts to prevent oxidation. The assembly can be removed once the molten brazing filler metal has solidified. dip brazing is an economical method of brazing multiple joint brazed parts, and large size dip brazing salt baths can help to dip braze a batch of. brazing is a fascinating process that connects metals using a filler material heated to a specific temperature range. dip brazing is a widely used method in manufacturing and engineering industries for joining metal components. To braze is to join two or more pieces of metal by means of flowing a filler metal between the joint interfaces.

Brazing For Beginners at Brandon Murillo blog

What Is Dip Brazing Process brazing is a fascinating process that connects metals using a filler material heated to a specific temperature range. dip brazing is a widely used method in manufacturing and engineering industries for joining metal components. dip brazing is an economical method of brazing multiple joint brazed parts, and large size dip brazing salt baths can help to dip braze a batch of. In this article, we’ll dive. what is dip brazing? To braze is to join two or more pieces of metal by means of flowing a filler metal between the joint interfaces. brazing is a fascinating process that connects metals using a filler material heated to a specific temperature range. The assembly can be removed once the molten brazing filler metal has solidified. Brazing flux is applied to the parts to prevent oxidation.

From www.thomasnet.com

Key Factors to Consider Before Beginning the Dip Brazing Process What Is Dip Brazing Process brazing is a fascinating process that connects metals using a filler material heated to a specific temperature range. dip brazing is an economical method of brazing multiple joint brazed parts, and large size dip brazing salt baths can help to dip braze a batch of. To braze is to join two or more pieces of metal by means. What Is Dip Brazing Process.

From exovxubli.blob.core.windows.net

Brazing For Beginners at Brandon Murillo blog What Is Dip Brazing Process dip brazing is a widely used method in manufacturing and engineering industries for joining metal components. dip brazing is an economical method of brazing multiple joint brazed parts, and large size dip brazing salt baths can help to dip braze a batch of. In this article, we’ll dive. The assembly can be removed once the molten brazing filler. What Is Dip Brazing Process.

From www.chalcoaluminum.com

All About the Aluminium Brazing Process Chalco Aluminum What Is Dip Brazing Process dip brazing is a widely used method in manufacturing and engineering industries for joining metal components. brazing is a fascinating process that connects metals using a filler material heated to a specific temperature range. Brazing flux is applied to the parts to prevent oxidation. To braze is to join two or more pieces of metal by means of. What Is Dip Brazing Process.

From exomeviih.blob.core.windows.net

Aluminum Dip Brazing Design Guide at Kristen Felix blog What Is Dip Brazing Process dip brazing is a widely used method in manufacturing and engineering industries for joining metal components. Brazing flux is applied to the parts to prevent oxidation. To braze is to join two or more pieces of metal by means of flowing a filler metal between the joint interfaces. what is dip brazing? brazing is a fascinating process. What Is Dip Brazing Process.

From georgeindustries.com

Aluminum Brazing Dip Brazing & Vacuum Brazing Industries What Is Dip Brazing Process In this article, we’ll dive. brazing is a fascinating process that connects metals using a filler material heated to a specific temperature range. what is dip brazing? dip brazing is a widely used method in manufacturing and engineering industries for joining metal components. dip brazing is an economical method of brazing multiple joint brazed parts, and. What Is Dip Brazing Process.

From www.slideserve.com

PPT Mechanical Fastening Processes Brazing PowerPoint Presentation What Is Dip Brazing Process what is dip brazing? To braze is to join two or more pieces of metal by means of flowing a filler metal between the joint interfaces. dip brazing is a widely used method in manufacturing and engineering industries for joining metal components. The assembly can be removed once the molten brazing filler metal has solidified. brazing is. What Is Dip Brazing Process.

From www.youtube.com

Brazing Process Animation YouTube What Is Dip Brazing Process what is dip brazing? The assembly can be removed once the molten brazing filler metal has solidified. To braze is to join two or more pieces of metal by means of flowing a filler metal between the joint interfaces. dip brazing is a widely used method in manufacturing and engineering industries for joining metal components. Brazing flux is. What Is Dip Brazing Process.

From aqcinspection.com

What is Brazing ? Where is brazing process used ? AQC Inspection What Is Dip Brazing Process To braze is to join two or more pieces of metal by means of flowing a filler metal between the joint interfaces. brazing is a fascinating process that connects metals using a filler material heated to a specific temperature range. dip brazing is a widely used method in manufacturing and engineering industries for joining metal components. Brazing flux. What Is Dip Brazing Process.

From www.youtube.com

Rantec Antennas Dip Braze Process Rough Cut YouTube What Is Dip Brazing Process To braze is to join two or more pieces of metal by means of flowing a filler metal between the joint interfaces. brazing is a fascinating process that connects metals using a filler material heated to a specific temperature range. dip brazing is a widely used method in manufacturing and engineering industries for joining metal components. what. What Is Dip Brazing Process.

From fractory.com

Brazing Explained Definition, Process, Types Fractory What Is Dip Brazing Process dip brazing is an economical method of brazing multiple joint brazed parts, and large size dip brazing salt baths can help to dip braze a batch of. brazing is a fascinating process that connects metals using a filler material heated to a specific temperature range. Brazing flux is applied to the parts to prevent oxidation. In this article,. What Is Dip Brazing Process.

From www.rhhfranks.co.uk

Special Processes — RHH FRANKS What Is Dip Brazing Process Brazing flux is applied to the parts to prevent oxidation. dip brazing is a widely used method in manufacturing and engineering industries for joining metal components. brazing is a fascinating process that connects metals using a filler material heated to a specific temperature range. dip brazing is an economical method of brazing multiple joint brazed parts, and. What Is Dip Brazing Process.

From www.mechero.my

What is Brazing Process? Brazing Types & Applications What Is Dip Brazing Process dip brazing is an economical method of brazing multiple joint brazed parts, and large size dip brazing salt baths can help to dip braze a batch of. what is dip brazing? To braze is to join two or more pieces of metal by means of flowing a filler metal between the joint interfaces. In this article, we’ll dive.. What Is Dip Brazing Process.

From www.rantecantennas.com

Dip Braze Dip Brazing Services Rantec Microwave Systems What Is Dip Brazing Process Brazing flux is applied to the parts to prevent oxidation. brazing is a fascinating process that connects metals using a filler material heated to a specific temperature range. The assembly can be removed once the molten brazing filler metal has solidified. In this article, we’ll dive. dip brazing is an economical method of brazing multiple joint brazed parts,. What Is Dip Brazing Process.

From www.rantecantennas.com

Dip It 5 Things You Wish You Knew About the Dip Brazing Process What Is Dip Brazing Process Brazing flux is applied to the parts to prevent oxidation. The assembly can be removed once the molten brazing filler metal has solidified. dip brazing is an economical method of brazing multiple joint brazed parts, and large size dip brazing salt baths can help to dip braze a batch of. To braze is to join two or more pieces. What Is Dip Brazing Process.

From exovxubli.blob.core.windows.net

Brazing For Beginners at Brandon Murillo blog What Is Dip Brazing Process To braze is to join two or more pieces of metal by means of flowing a filler metal between the joint interfaces. In this article, we’ll dive. what is dip brazing? The assembly can be removed once the molten brazing filler metal has solidified. dip brazing is an economical method of brazing multiple joint brazed parts, and large. What Is Dip Brazing Process.

From fractory.com

Brazing Explained Definition, Process, Types Fractory What Is Dip Brazing Process what is dip brazing? In this article, we’ll dive. To braze is to join two or more pieces of metal by means of flowing a filler metal between the joint interfaces. The assembly can be removed once the molten brazing filler metal has solidified. dip brazing is a widely used method in manufacturing and engineering industries for joining. What Is Dip Brazing Process.

From vulcangms.com

What can a brazing process do for you? What Is Dip Brazing Process what is dip brazing? dip brazing is an economical method of brazing multiple joint brazed parts, and large size dip brazing salt baths can help to dip braze a batch of. Brazing flux is applied to the parts to prevent oxidation. dip brazing is a widely used method in manufacturing and engineering industries for joining metal components.. What Is Dip Brazing Process.

From www.rantecantennas.com

Why You Should Choose Our Dip Brazing Service Rantec What Is Dip Brazing Process The assembly can be removed once the molten brazing filler metal has solidified. dip brazing is an economical method of brazing multiple joint brazed parts, and large size dip brazing salt baths can help to dip braze a batch of. In this article, we’ll dive. To braze is to join two or more pieces of metal by means of. What Is Dip Brazing Process.